|

||

|

Trends in Factory Automation: The Internet of Things

Factory automation technology is entering a period of rapid change and technical advances designed to improve operations. Factory processes will be more efficient with higher reliability and better quality output. Requirements for operator intervention in manual settings or in open control loops will become increasingly rare and even closed loop controls will change as intelligent sensors and universal connectivity become commonplace. Fast networks will allow factory data to be available outside the plant in real time and secure networks will replace present-day slow, insecure communications. The framework that drives these changes is the Internet of Things concept. When everything is connected, increased efficiency is possible and improved communication allows access to data where and when it can best be used. Machines can communicate directly via machine-to-machine interfaces and factory data can be made available to customers. Industrial computers become the heart of this revolution, handling data processing, storage, connectivity and interfaces. Embedded in the factory, these compact and rugged units lead the transition to factory automation via the IoT. This year, 2015, about 15 billion (1) devices will be connected to the Internet. By 2020 there may be as many as 50 billion devices (2). That number includes computers, laptops, smartphones and tablets, but most of the devices will be intelligent sensors and embedded processors. This trend has been held back by the limited number of IP or Internet Protocol addresses available under the previous IP version 4. The new IP version 6 has more than enough addresses for accommodating this increase in connections and its rapid and widespread adoption has removed the IP address bottleneck. Once IP addresses are available for assignment to each networked device, Internet communication links can transmit the available data to actuators for carrying out commands, to processors for collection and storage, to remote computers for analysis and to user interfaces for further action. Instead of sending process signals and alarms to operator control desks for further process-related action, the networks conduct the data to the industrial computers on the factory floor, and these initiate further action as required. The computers store all the data and the corresponding actions and send reports to the people who need the data. Company management and customers use their data to plan business strategies and projects. When additional information is required to make an informed decision, users can call up additional data from storage and drill down to get at causes and find solutions.

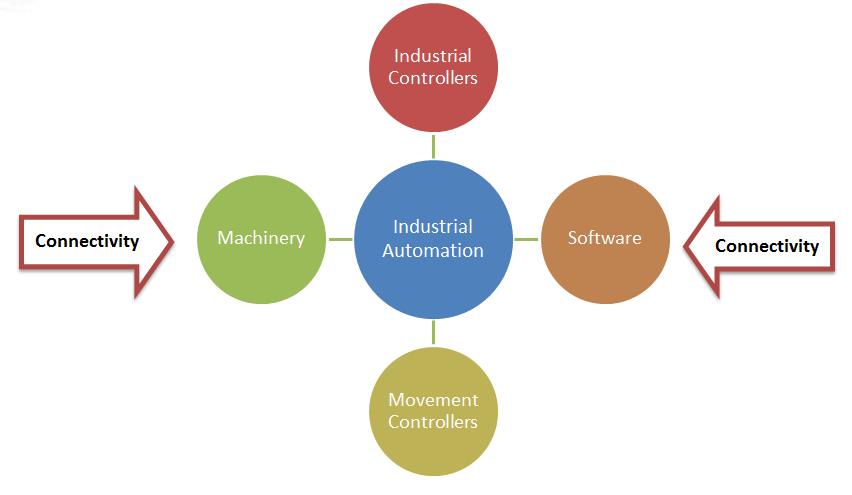

For example, on a new IoT automated production line, sensors are everywhere. Some have traditional functions that detect temperatures or pressures or the presence of a metal box or sheet. Others have additional analytical functions that evaluate whether a situation is abnormal. All have communication capabilities and send out their data together with their IP address. The IoT concept is to create a digital image of the process in real time so that even remote users can know what is going on in the factory. The factory line data forms the basis for the digital image, but the raw data is not relevant for users who are not familiar with the process. The local embedded controllers, processors and industrial computers take the data and convert it to information. Users want to know how many products have been completed, whether there has been a component failure, whether quality control has detected an unusual number of problems and whether inventory is low or has built up. The hardware can take the data from the sensors as input and create output relevant for users. It receives the data and sends out the processed results. Recipients of the information can take corresponding actions or analyze it further to create meaningful reports. Industrial computers controlling inventory might receive data that the factory will have to produce an increased volume of a particular product. Sensors reading bar codes or RFID (radio frequency identity) tags, count parts entering and leaving the warehouse so the computer can call up the number of parts in stock. Comparing the quantity on hand with the number that will be required, the computer can initiate an order placement with the supplier for any needed additional parts. Based on the production schedule, it can request shipment of the additional parts to match the requirements of the production line. Should the actual production volume exceed or fall short of planned targets, the computer can adjust the delivery times to match the new plan. Reports on the actual parts supplied and used are sent to the purchasing department for payment. The supplier's direct connection to the factory makes the supply and delivery process more efficient. Embedded processors can be used to monitor for fault conditions. If a bearing overheats, its temperature sensor sends the temperature data to the processor for further action. From the temperature data profile, the processor can determine how serious the overheating problem is and what kind of service is required. If the bearing is only overheating slightly, the processor can schedule maintenance during the next scheduled shutdown. If the overheating is serious but not critical, the processor might request a service call from the service provider and schedule it at the end of the current production run. If the overheating is critical, the processor might carry out an orderly shutdown of production and request an emergency service call. At the same time, the processor might consider shutting down the machine with the faulty bearing and using another machine if available. In each case, the optimal solution is selected from the possible options and corresponding reports go to the departments responsible. Connected factories using IoT automation technology can make important data available outside the factory as well. If a customer has ordered a key component for his project and has to schedule his work and his project's completion around delivery of this equipment, a supplier can give the customer direct access to production line information. A customer will be able to track manufacturing progress of his order through production, testing and shipment and plan his work based on reliable data. Such data can either be made available in real time on a secure web page for the particular customer. Notifications of key milestones, such as start of machining, completion of assembly, start of testing and shipment of products can be sent to the customer automatically. In either case, the customer can adjust his project schedule to reflect the situation accurately. These examples give an overview of how the trend toward IoT-based factory automation can make use of process information effectively. When data is available throughout the factory, it can run more efficiently. When factory information is available to outside users, the whole supply chain can benefit (3). Connectivity Connectivity technologies provide the links that make the IoT possible. Both wired networks and wireless communication play important roles. Wired fast Ethernet with IP addressing is spreading into areas such as sensor links which previously communicated via simple circuits or proprietary protocols. Mobile communications are taking over from wired networks when the speed and capacity are adequate. Local area networks based on WiFi 802.11 fill in the wireless gaps between short-range communications technologies such as RFID and main Internet connections or cellular networks. When IP addresses are assigned down to the sensor level, data analysis and processing become flexible and adaptable. If more data points are needed, additional data can be obtained from the sensor by calling up readings more frequently. Changes in the process become changes in software applications.

Wired Ethernet is still the workhorse of factory automation (4) and has unparalleled bandwidth, speed and reliability. Possible cable damage and broken connections are a disadvantage that designers can address with mechanical protection of wires and software checking of links by regularly calling up the IP addresses of linked devices. High immunity to interference from electric machinery is a plus. The latest WiFi 802.11 standards are fast enough to replace Ethernet in many applications and the corresponding wireless devices are easier to access. While adding an Ethernet device requires running a cable to the place of installation, a WiFi device can be placed anywhere and it will connect securely to the wireless network. The change to WiFi from wired Ethernet is driven by the inherent diagnostic capabilities of the 802.11 protocol. When the communication capability of a node or a device fails, the wireless network generates an error message. While the access to most of the IoT information is via the Internet, some controllers and processors may have the capability to send messages via cellular networks. Notifications can be sent through mobile telephone calls or text messages and service calls to mobile personnel can be automated. Other information may only be available via web pages or email but formats have to be compatible with mobile device screens or formatted as mobile sites for display on mobile devices. Hardware

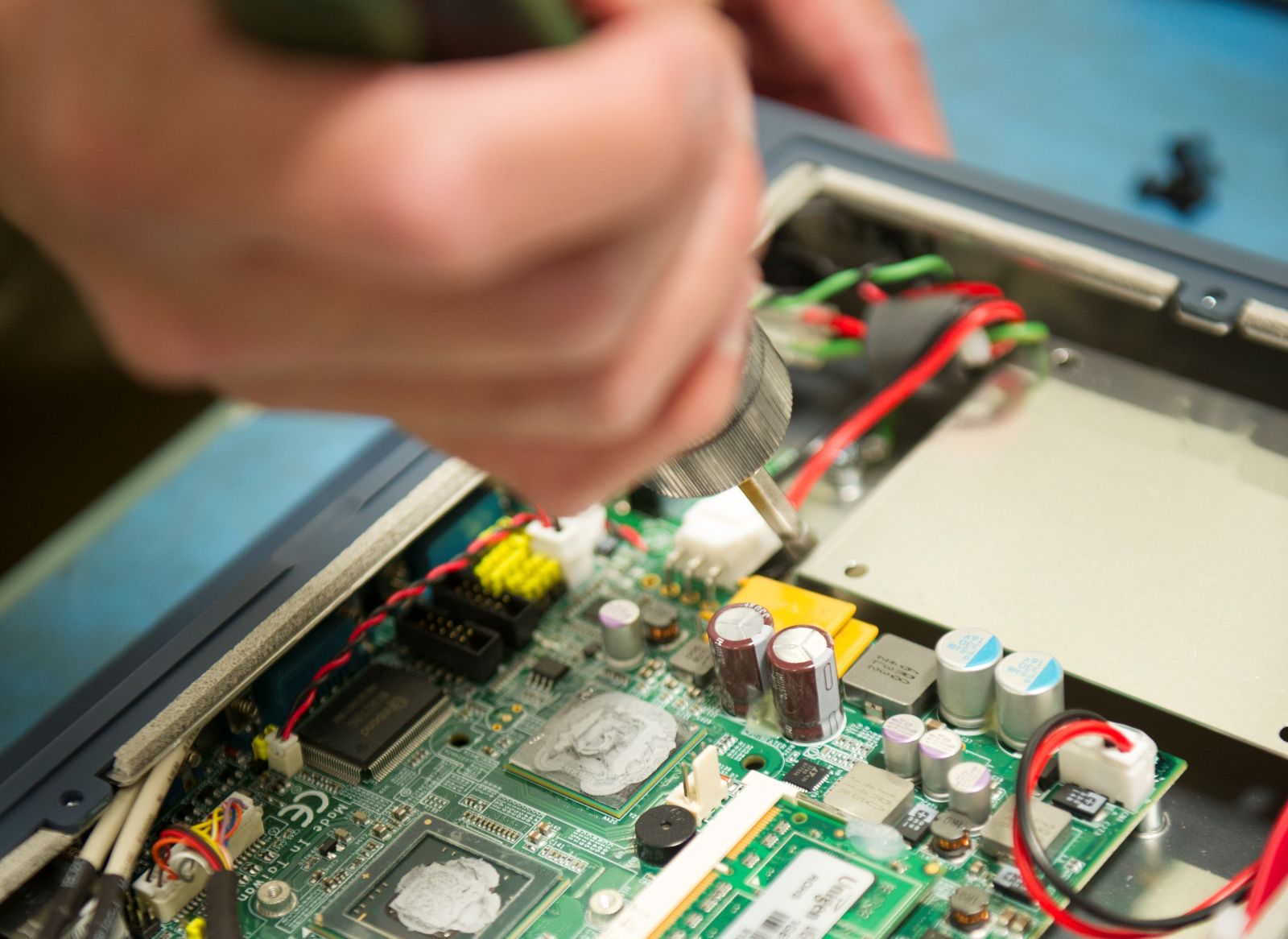

Industrial Controllers (Embedded Systems) The workhorses of factory automation are the controllers. Some of the most common industrial controllers used in factory automation environments are created on a need-based basis and have become more advanced over the years. Computer technology has evolved and opened doors to new ways to production process control and data communications. Factory automation has become more complex and requires the use of embedded controllers in many areas. For example, an industrial embedded controller used in factory automation can be used as a controlled tool for machine-to-machine (M2M) communications. It is essentially a rugged and high-performing computer. With fast processors, multiple communication ports, several storage possibilities and a highly reliable design, these controllers can take the rough conditions of the factory floor and deliver the power needed for IoT advanced processing capabilities. Many factory operations prefer fanless controllers for their noiseless operations and ability to manage their own heat dissipation without an additional part such as a fan, to help increase the production line’s operational reliability. These controllers can offer the latest in computing technology such as the Intel® Core™ I family central processing unit (CPU). Such powerful embedded controllers are vital to the successful implementation of IoT functions. For example, a production process that involves the use of chemicals might have a temperature sensor that delivers a continuous temperature reading in an effort to control the chemical reaction. The sensor communicates via Ethernet or Wi-Fi and has an IP address that allows the controller to identify the location of the temperature reading. As the chemical heats up, the embedded system may also change how quickly the chemical is heated by controlling the power delivered to the heater. The embedded system can also store the temperature-reading data and the respective power level used by the heater for future reference and analysis – or can make them available to technicians in real time if required. The controller recognizes trends that tend toward failure levels and might take action to reduce loading or otherwise compensate for problems. Technicians can either immediately view the problems in real time after receiving an alarm from the controller or can analyze what went wrong at a later date. A complete image of the process is available from data captured, stored and/or transferred by the controller. Quality control personnel can identify the process conditions that led to the quality issues upon reviewing the actual process values during the time the problems occurred. Solutions often do not require major changes in equipment or cabling because the important parameters can be changed or re-programmed via the embedded system used to control the production line operation. A. Programmable Logic Controller

This basic and most popular type of controller has been around for over 50 years. Created in the 1960s to replace relay-based systems, early programmable logic controllers (PLCs) controlled simple tasks, required dedicated terminals for programming, had very limited storage capacity, and lacked remote I/O or communications capabilities (6). Most factory operations use the programmable logic controllers to issue commands in the assembly line. They can be used to control repeated functions based on the data they receive from sensors and the programming logic. For example, if a chemical is heated to a given temperature, a temperature switch might close when the correct temperature is reached. The PLC receives the signal from the temperature switch and is programmed to then shut off the heater. Alarms are handled in the same way. If a motor overheats or a pressure rises above safe levels, the PLC issues an alarm to the production line operators or, in severe cases, shuts down the line. More recent controllers which incorporated newer technologies in the design can easily be re-programmed to change the commands. The difficulty is found more in making production process changes due to the lack of data available for analysis and challenges in gaining access to them in a timely manner when available. This is due to the sensors’ and actuators’ limited capabilities. Important information about the details of the process may not be detected, is not readily available for analysis and cannot be captured and stored easily. In the past, there were disconnections between the sensors and the PLC for data capture and storage. Quality control issues originating in the production process often could not be identified because the information about possible deviations in process variables, i.e., temperature fluctuation, were not recorded and technicians had to engage in detailed modeling after the fact to try and reproduce past conditions leading to the problems. Communications via PLCs may have been limited to a range within local operational areas, i.e., production lines, or within the manufacturing facility. Currently, with the IoT concept emerging as an important trend that influences all aspects of factory automation, PLCs are becoming more sophisticated and offer features that allow connectivity and communications beyond the original capabilities. B. Programmable Automation Controllers (PACs)

C. Remote Terminal Units (RTU)

D. Industrial PC (IPC)

E. Vision System

Some vision systems combine tracking with inspection with an optical character recognition (OCR) feature for quality control and verification processes. Current technology allows for varying degree of sophistication for these vision systems. Each project’s requirements will depend on the application’s complexity and its scale. F. Fieldbus Connecting devices, in the past, required extensive cabling and protocols that allow effective communication among them. Progressing from connecting only two devices at a time with a cable and offering only one communication parameter for one device for control, we are now entering an era of less cabling and more communications and control capabilities. One of the inventions to improve the automation process is the fieldbus. This common real-time distributed control industrial network system was introduced to replace Bitbus – the very first technology for connecting and communicating devices. It was launched by Intel® in the 80s. Since then, one consistent global standard has been the desire of many in the industry. Nevertheless, many standards have been developed and thrived. A few major ones are mentioned below: a. Controller Area Network (CAN Bus)

b. EtherCAT Master

c. IoT Gateway

The main function of IoT gateways is to act as an interface for legacy and non-IP devices (7). A machine may have a number of limit switches and other simple sensors. The cost of adding IP functionality to all these devices may not be justified by the possibility of accessing them directly from the Internet. Instead, an IoT gateway takes the signals, stores data about the origins of each data point and makes the information available on Ethernet, WiFi or cellular networks. The unit is the bridge that allows the IoT concept to operate even in installations where devices are not capable of Internet connectivity on their own. Intel® offers a software stack that includes security, manageability and connectivity capabilities with Wind River and McAfee apps and services integrated to work with hardware solutions. Panel PCs (Human Machine Interface device)

Panel PCs are commonly used as production line user interface and controllers. To fulfill these functions, a panel PC has to have many of the same physical characteristics as the embedded controller. The same rugged enclosure, fanless operation and protection against harsh environments and fluctuating temperatures are required. For the I/O interfaces, the same Ethernet, USB and serial ports as well as audio and additional monitor connectors are important – along with storage capabilities and expansion slots for additional functions and customization.

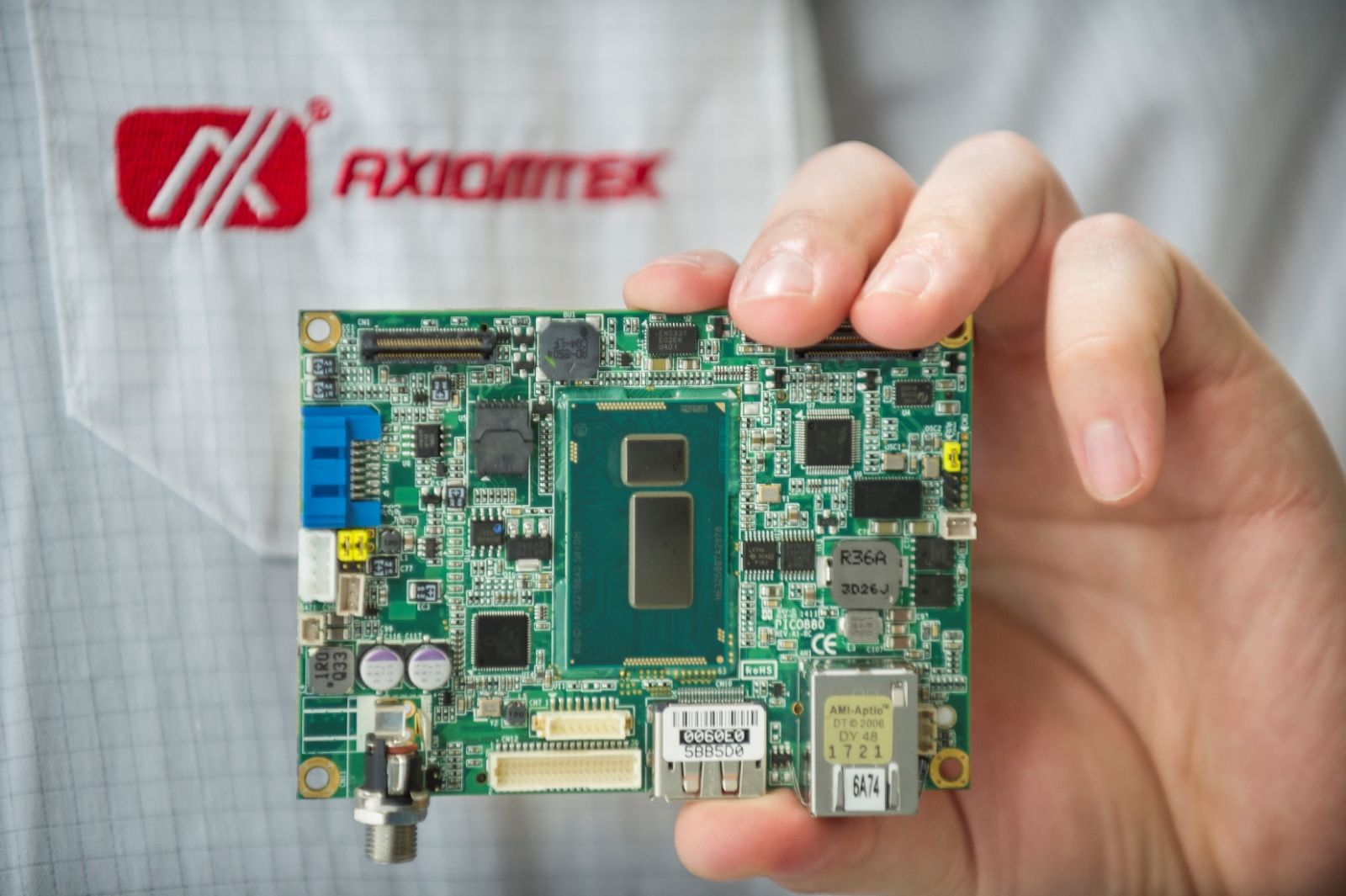

Embedded Motherboard and Systems on Module

Compact form factors such as COM Express, PICO-ITX, Nano and 3.5” boards having a variety of platforms including x86, RISC, etc. have become more advanced and able to withstand harsh operating conditions. These 2.5” PICO-ITX boards can offer low power consumption and a wide operating temperature range of -20°C to +70°C. They can offer high computing performance using Intel® or AMD processors. Mid-size form factors such as mini-ITX, ITX or PICMG are preferred by systems integrators whose projects do not require compact form factors. These boards have powerful socketed CPU, better thermal performance and richer and greater flexibility for I/O interfaces. Communication capabilities including wireless can be offered via a PCI or PCIe feature as well as a SIMs slot to help the integrated device communicate with others or the control center –all in support of the IoT concept. Software integration

Factory management will often prefer to run applications on standard platforms with standard software. Integrating these computers into the overall IoT factory automation concept via a shared network, common information storage locally and in the cloud, and shared access to all important process data through the IP addresses increases flexibility and computing capabilities – while leaving the direct automated process management to the embedded controllers. IoT Applications

The IoT concept lends itself to solutions of specific problems in manufacturing. Process efficiency challenges, scheduling, logistics and quality control are all issues that could benefit from better, more timely and more accurate information. The IoT can deliver the information that is required in real time with high accuracy. Companies are using these capabilities to improve their operations. Medical device manufacturers are trying to reduce costs while complying with regulations and delivering consistent quality (8). An IoT approach lets them identify bottlenecks in production, unnecessarily high costs and quality issues easily and precisely. They can see from production line data where inventory or material on hand is piling up due to lack of capacity at a given production point. They can track costs to make sure high-cost parts and processes deliver corresponding benefits. When products fail, they can track the serial number back to the production line and see exactly how that product was manufactured and where the failure originated. Solutions are often software based and can be implemented without major production disruptions. The information containing the problems and the tools for implementing solutions are both online. Automotive manufacturers already use Just-in-Time deliveries to reduce the cost of inventories (9). Many functions of the Just-in-Time concept can be completely automated using IoT tools. The decisions to be made, to place orders based on materials on hand and production schedules, can be handled effectively by computers. At the other end of the production line, JiT means producing only what is needed. Ideally, a vehicle rolls off the production line just as an order for the vehicle comes in. The comprehensive information available under the IoT concept, including complete historical data from past orders, can help implement such a process. For large online and big box suppliers, superior logistics are a key to ensuring rapid and reliable deliveries (10). Under an IoT implementation, the location of products, whether on their way to warehouses or to customers, is always known. RFIDs, bar code readers and GPS tracking allow the companies to optimize shipping, routing and deliveries while at the same time reducing costs. An IoT-enabled warehouse always has exact data on what it contains and where each item is located. That information, combined with knowledge of what is coming and what is scheduled to go out, allows companies to optimize their shipping and storage processes. Benefits

The availability of data in real time can reduce downtime as abnormal conditions are identified as they happen and solutions are accessible rapidly. An embedded controller linked to sensors in the process can often predict possible failures and take action or request a service call. Technicians have remote access to sensor data and to actuators allowing them to issue commands. The production line may not have to shut down and the causes of failures can be identified and resolved reliably. Reduced downtime and better management of scheduling and shipping can reduce production costs. More importantly, the availability of seamless data points lets technicians and management identify where they should be focusing their efforts to gain the highest improvements. High costs, bottlenecks, failure sources and sources of production delays become obvious in an analysis of the data, and the overall digital image of the process provided by the comprehensive data set shows the way toward optimal solutions. Lower production costs, faster shipping, JiT supply, and reduced failure rates lead to an overall increase in efficiency of the automated process. Enhanced communication between manufacturers, suppliers and customers leads to better communication of needs. Increased customer satisfaction due to improved quality control allows companies to retain customers. The IoT factory automation concept can result in a more efficient supply chain with benefits for all participants. Summary

For existing installations, a gradual implementation with IoT gateways is possible. Barriers to IoT implementation are cost, identification of competent vendors and training of employees. Developing an IoT-based factory automation concept is challenging and requires additional skill sets that current employees may not have. That said, doing nothing has a cost as well when competitors become more efficient and offer products at a lower cost with higher quality. To make the connected factory of the IoT work, extensive planning and the development of firmly based technical concepts specific to particular factories and processes are required. Technicians have to identify what data is important, how it will be captured and how it will be used. The actuators that carry out the commands controlling the process must be specified. Adequate controller and computer capacity has to be installed. The software to run the process is a key factor for a successful implementation. The implementation of a complete IoT concept for a factory can be costly and work-intensive but the benefits can be substantial. Replacement of existing equipment with newer, IoT-friendly ones can be done in phases. Once the important controllers and the HMI device are in place and in operation, the evaluation and analysis of important data can be brought into play. The process, then, can be optimized and efficiency enhanced. The bottom-line goals of improving productivity, product quality and return on investment will be recognized. Sources |

||

| www.axiomtek.com |

Copyright 2020 Axiomtek Co., Ltd. All Rights Reserved

|

|

.jpg)

At the factory level, installed hardware consists of sensors and actuators, controllers and processors, and user and communication interfaces. The sensors and actuators, whose function is to measure physical variables and carry out commands, don't change much from traditional units under the IoT concept. The sensors still have thermal, physical or magnetic detectors that measure process conditions, and the actuators are still the relays, valves, motors and switches that control the process. The main difference with these units is the presence of electronics that allow IP-based communication, with each device receiving an IP address, a communication module and basic data processing capabilities. The real changes for IoT take place at the controller, processor and user interface levels (5). These units have to be able to receive data from the sensors, process the data and store it, issue commands based on the data they receive, and pass on processed and analyzed information for the users. Powerful embedded systems, panel PCs, motherboards and IoT gateways take over these functions.

At the factory level, installed hardware consists of sensors and actuators, controllers and processors, and user and communication interfaces. The sensors and actuators, whose function is to measure physical variables and carry out commands, don't change much from traditional units under the IoT concept. The sensors still have thermal, physical or magnetic detectors that measure process conditions, and the actuators are still the relays, valves, motors and switches that control the process. The main difference with these units is the presence of electronics that allow IP-based communication, with each device receiving an IP address, a communication module and basic data processing capabilities. The real changes for IoT take place at the controller, processor and user interface levels (5). These units have to be able to receive data from the sensors, process the data and store it, issue commands based on the data they receive, and pass on processed and analyzed information for the users. Powerful embedded systems, panel PCs, motherboards and IoT gateways take over these functions.

Many factories and warehouses have now opted for a vision system that incorporates the use of cameras - integrated into a controller unit as a part of production line automation, warehouse use and more. These vision systems are programmed to perform defined tasks using infrared, 3D, thermal cameras to inspect and monitor production line or inventory systems. Data from the inspection can also be captured and transferred for future or immediate analysis. A high-speed 3D camera can perform industrial inspection tasks with a great level of efficiency and accuracy which, in turn, can help reduce operational resources and costs.

Many factories and warehouses have now opted for a vision system that incorporates the use of cameras - integrated into a controller unit as a part of production line automation, warehouse use and more. These vision systems are programmed to perform defined tasks using infrared, 3D, thermal cameras to inspect and monitor production line or inventory systems. Data from the inspection can also be captured and transferred for future or immediate analysis. A high-speed 3D camera can perform industrial inspection tasks with a great level of efficiency and accuracy which, in turn, can help reduce operational resources and costs. EtherCAT is a real-time industrial Ethernet fieldbus technology that works with many automation applications. Developed by a company called Beckhoff Automation, the solution provides high performance and flexible topology for a wide variety of industrial automation uses. With EtherCAT, slave devices read data passing through immediately without having to interpret and copy. Performance is enhanced with a shorter cycle time. This popular fieldbus technology has an established worldwide user organization called the EtherCAT Technology Group (ETG) that consists of members such as industrial control hardware vendors, technology firms, OEMs and more. They provide standards that ensure interoperability and protocol compliance of EtherCAT devices. Among many member companies, Acontics Technologies is one of the leaders for EtherCAT technology. They provide an EtherCAT software stack that is ready to run and easy to port on a wide variety of operating systems. Some Industrial computer hardware manufacturers offer systems that come equipped with an EtherCAT software stack.

EtherCAT is a real-time industrial Ethernet fieldbus technology that works with many automation applications. Developed by a company called Beckhoff Automation, the solution provides high performance and flexible topology for a wide variety of industrial automation uses. With EtherCAT, slave devices read data passing through immediately without having to interpret and copy. Performance is enhanced with a shorter cycle time. This popular fieldbus technology has an established worldwide user organization called the EtherCAT Technology Group (ETG) that consists of members such as industrial control hardware vendors, technology firms, OEMs and more. They provide standards that ensure interoperability and protocol compliance of EtherCAT devices. Among many member companies, Acontics Technologies is one of the leaders for EtherCAT technology. They provide an EtherCAT software stack that is ready to run and easy to port on a wide variety of operating systems. Some Industrial computer hardware manufacturers offer systems that come equipped with an EtherCAT software stack..png) In existing installations or in factories where simple devices including sensors may not have IP communication capability, an IoT gateway can aggregate signals and act as a portal to the IP-enabled networks. IP communication requires some processing capacity at the device level and it is costly to implement. For installations needing reduced capital costs, using IoT gateways can save money. At the same time they can be programmed to block direct access to the sensors and actuators on the other side of the gateway.

In existing installations or in factories where simple devices including sensors may not have IP communication capability, an IoT gateway can aggregate signals and act as a portal to the IP-enabled networks. IP communication requires some processing capacity at the device level and it is costly to implement. For installations needing reduced capital costs, using IoT gateways can save money. At the same time they can be programmed to block direct access to the sensors and actuators on the other side of the gateway.

At the heart of each controller and panel PC lies a motherboard. A systems integrator cannot design and deploy an embedded controller or an all-in-one panel PC without this critical element. A variety of form factors are available to suit different application needs.

At the heart of each controller and panel PC lies a motherboard. A systems integrator cannot design and deploy an embedded controller or an all-in-one panel PC without this critical element. A variety of form factors are available to suit different application needs.