Axiomtek's and Axiomtek Systems' Professional Engineering Services can help our customers shorten their development cycle, reduce design efforts and costs, speed up the time to market, and achieve a higher return on investment.

Axiomtek's Professional Engineering Services offer overall project support or task-specific assistance during the development, testing and deployment phases of your mission-critical projects. Our services include design assistance, thermal solutions, embedded software, and modularized accessories. Our Axiomtek's Value-Added Engineering Services include automated-test procedure, life cycle management, high mix systems integration, system-level design, forced routing, direct order fulfillment and more. Select the service menu on the right for additional details on each service offering.

Axiomtek's Professional Engineering Services offer overall project support or task-specific assistance during the development, testing and deployment phases of your mission-critical projects. Our services include design assistance, thermal solutions, embedded software, and modularized accessories. Our Axiomtek's Value-Added Engineering Services include automated-test procedure, life cycle management, high mix systems integration, system-level design, forced routing, direct order fulfillment and more. Select the service menu on the right for additional details on each service offering.

Axiomtek has become the premier value-added service provider for systems integration assistance and project management. Many leaders in a variety of industries have entrusted Axiomtek with their outsourcing needs. Both our Massachusetts and City of Industry locations are ISO9001 certified. Axiomtek USA is known for its expertise in providing COTS-based integration services, along with engineering design, manufacturing and logistics services for companies that are deploying mission critical platforms. Axiomtek's overall customer-focused and personalized approach has helped many of our clients succeed in achieving their goals in the most effective way with remarkable results.

For more information about Axiomtek products and customized design assistance, please email us at solutions@axiomtek.com or call us at 1-888-GO-AXIOM (1-888-462-9466).

Engineering Services

Automated-Test Procedure

Called "ATP". We can develop a testing framework with a user interface that generates events to validate that the functional operation of our customer's system is within a specified tolerance. An ATP is geared towards eliminating human errors and increasing operational efficiencies.

Design Services

Design Services

- Board-level design

- System-level design

- PCBA design

- Mechanical design

- Thermal analysis

- Agency certifications-UL,FCC,CSA

- SDK and board support packages

- Reference Designs

- COTS level system and design

Our value-added services leverage our expertise across multiple embedded hardware and software standards. Where a customer has difficulty making a 100% COTS offering work, we offer derivative designs that incorporate a hybrid mix of both standard products as well as custom in order to deliver a perfect solution. This approach may require mechanical design modifications, circuit design, board support package development and image creation. Additionally, we can conduct pre-scan and thermal tests before assisting our customers with the agency certification effort.

Integration & Manufacturing Services

Process Documentation

Process Documentation

Otherwise known as a "build document". We create a build/test document which is a logical arrangement of steps to follow in order to successfully and consistently assemble our customer’s system. Properly written process documents insure that our customer’s product is built exactly how they specify it to be

High Mix Systems Integration

We excel in integrating and managing complex builds consisting of multiple third-party HW and SW subassemblies both in COTS as well as custom designs.

Safety Stock Maintenance

Materials in stock that are held above and beyond the actual demand for that material, hence creating a safety stock. Safety stock programs are designed to reduce long lead times.

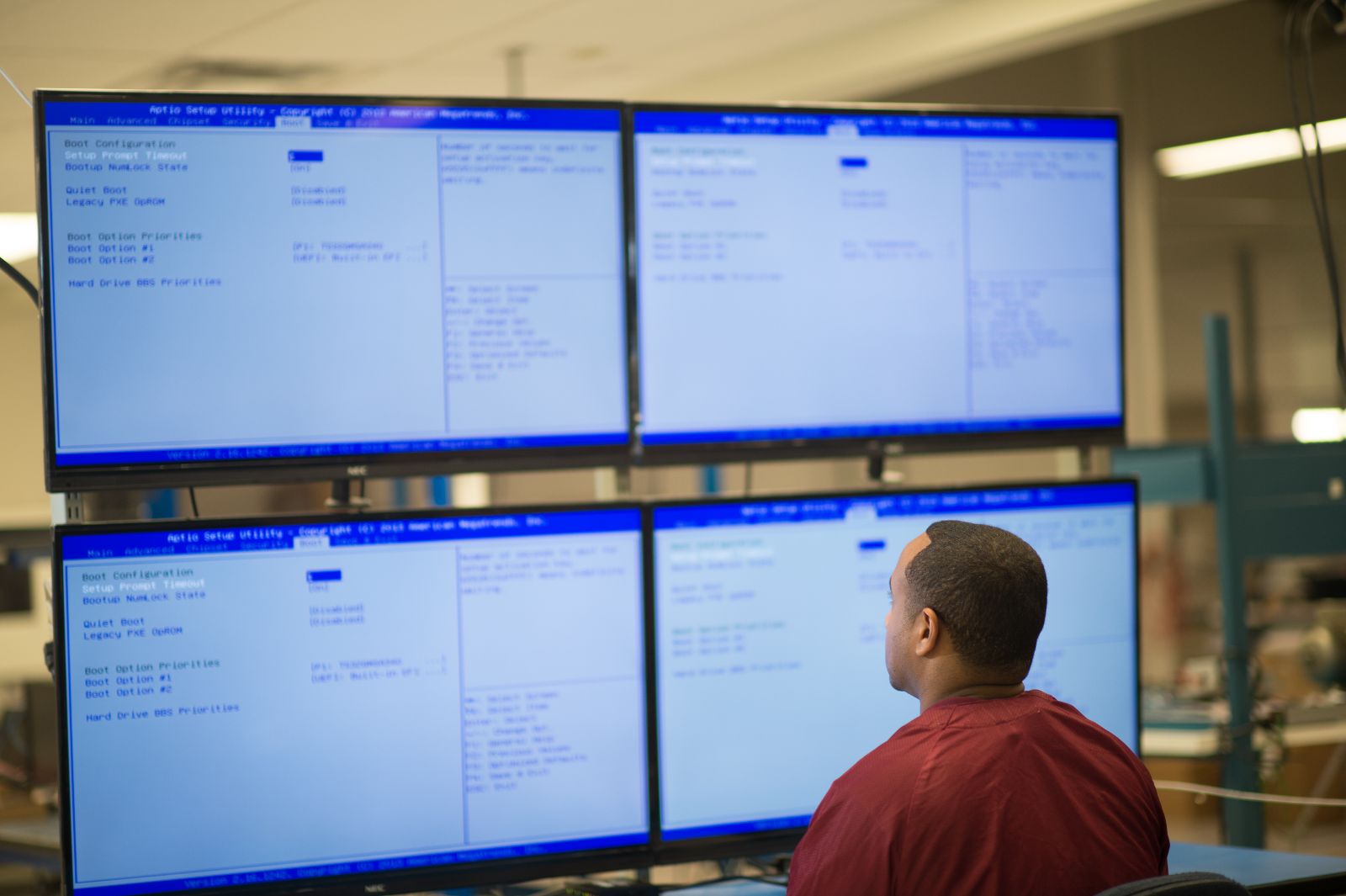

Image Load and Test

We have expertise in receiving our customer's image, validating it on their system platform, loading it, and providing testing services to insure its proper functional operation on the platform. Image loads can be done through an automated and fail-safe production network method based on a customized gang loading approach.

We have expertise in receiving our customer's image, validating it on their system platform, loading it, and providing testing services to insure its proper functional operation on the platform. Image loads can be done through an automated and fail-safe production network method based on a customized gang loading approach.

Forced Routing

Quality data collection center through customized product routings. Forced routing allows you to create a quality plan per a customer SKU or a specific supplier part number.

- Customized In-Process Quality Metrics

- Customer Portal

ERP/MRP

Features: sales order entry, bill of material creation, daily MRP regeneration, planned order reports, shop floor control, and flexible warehouse locations.

New Product Introduction

Otherwise known as "NPI". We have an ISO controlled process for the release of new products which includes doc control, drawings, assembly docs, checklists, test procedures and final QC. This process ensures a smooth transition from the requirement definitions through the hand-off to manufacturing. The customer's involvement will culminate with an official sign off of the source control document.

MRB

The process where a team of people reviews discrepant material for disposition. Popular dispositions are: return to vendor, repair, scrap, and use as is. MRB data is critical in maintaining a high level of quality in our customer's product.

IPC-A-610/WHMA-IPC-620

We have IPC610/620 certified in-house resources including a WHMA/IPC-A-620 trainer.

Life Cycle Management Services

Configuration Management

Configuration Management

We work with selected suppliers to develop a configuration agreement to ensure that critical components cannot be changed without notification. This is otherwise known as "BOM Locking". A full BOM lock eliminates configuration uncertainty which can shut a production line down.

Product Life Cycle Management

- Bill of Material Management

- EOL Surveillance and Notification

Ensuring that our customers reap the benefit of a component's full product life cycle is very important to us. With this mind, during the product selection process, due diligence is exercised to disclose where every COTS item is in its life cycle and decisions are made as to the viability of the part. Once selected, on a quarterly basis, we conduct an EOL surveillance on the list of material. The OEM is then notified of any part that is known to have an impending EOL. We can work with the OEM to help select a replacement part, bring it in for testing, and ultimately cut it into production as a qualified replacement part.